PROMIG XP Versions

| Item No | 360C | 360XP | 500XP | 650XP | |

|---|---|---|---|---|---|

| Cooling variants | |||||

| Gas | ● | ● | ○ | ○ | |

| Water | ○ | ○ | ● | ● | |

| Wire feeder system | |||||

| Built-in wire feeder system |

● | / | / | / | |

| Separately wire feeder system | / | ● | ● | ● | |

| Operation method | |||||

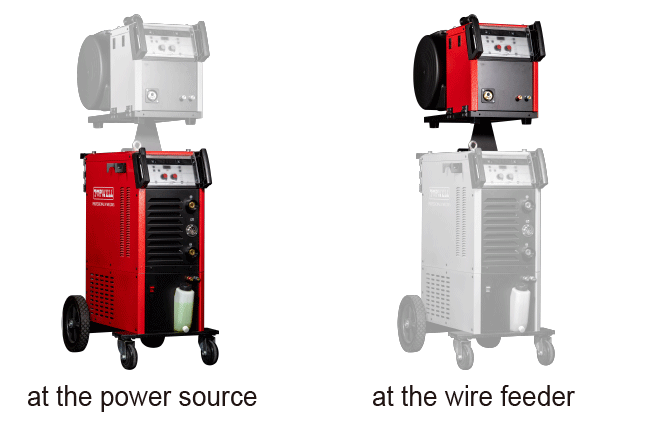

| At the main power source | ● | ● | ● | ● | |

| At the Wire feeder | / | ● | ● | ● | |

| At the remote control | / | ○ | ○ | ○ | |

| At the torch | ○ | ○ | ○ | ○ | |

● Standard options ○ Optionally available / Not Available

Advanced Processes Package

| Process | PROMIG 360C | PROMIG 360XP | PROMIG 500XP | PROMIG 650XP |

|---|---|---|---|---|

| Short Arc (refined dip transfer) | ● | ● | ● | ● |

| Pulse Arc | ● | ● | ● | ● |

| HSP (high speed pulse) | ● | ● | ● | ● |

| HSA (high speed spray arc) | / | ○ | ○ | ○ |

| UCA (ultra concentrated arc) | / | ○ | ○ | ○ |

| HPC (hybrid pulse control) | ○ | ○ | ● | ● |

| MDP (micro double process) | / | ○ | ○ | ○ |

| ULS (ultra low spatter) | / | ○ | ○ | ○ |

● Standard options ○ Optionally available / Not Available

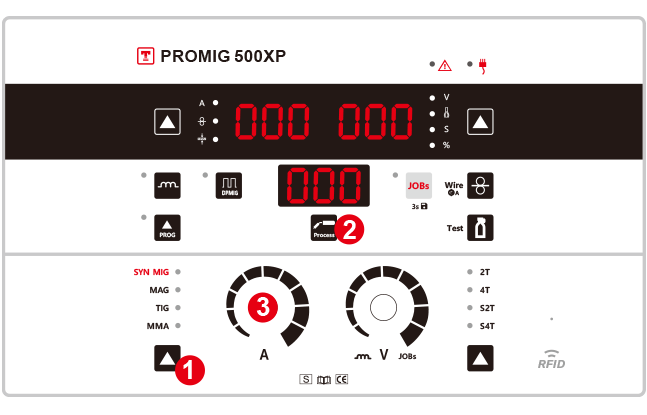

Easy to Use

3 steps To Achieve Weld Perfection

1.Select Processes-list No.

2.Adjust welding current.

3.Save it into JOBs.

(always the perfect setting by the synergic function using the material thickness)

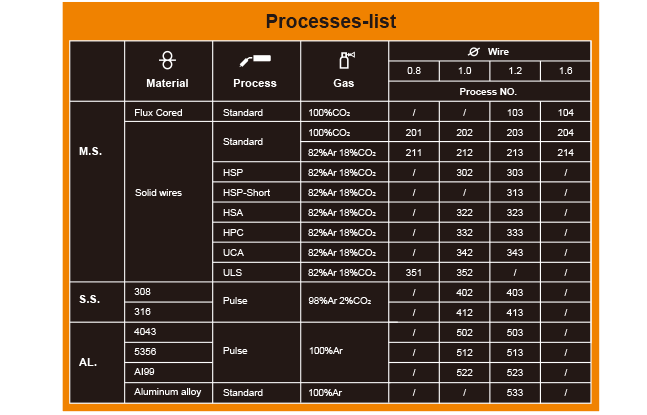

Process-list

To start welding, users can simply and quickly select a process No. according to any particular welding needs (based on material, process, gas, wire). A wide range of welding processes with perfect waves have been embedded into the well-displayed Topwell process-list.

Synergy Control

With the default synergy control, Topwell’s system can automatically synchronize the corresponding parameters based on the selected welding process and the adjusted current, which is easy and convenient for use. Users also can set the parameters manually when synergy is off.

Memory Storage Function

With the powerful storage with great capacity, up to 999 processes/JOBs can be saved in the system for later use. Users can easily re-save or recall previous processes with just one click. Working efficiency are greatly improved with Topwell’s memory funtion.

Flexible control mothods

You can regulate the machine everywhere ----- at the power source, at ....

Ready for Intelligent Fabrication

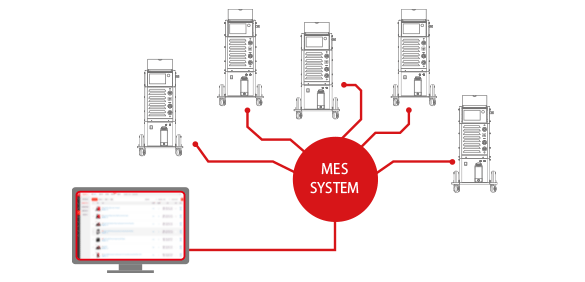

PROMIG XP Series is equipped with active user management and assigned NFC keys to set protection and permissions for parameter adjustment. It can also choose to connect to the MES system, which is more suitable for modern production data management.

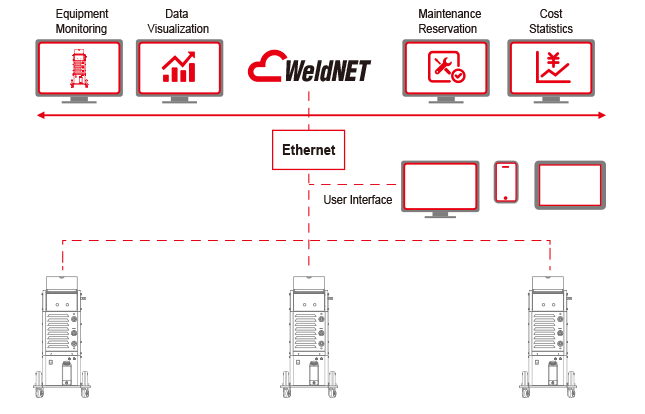

By connecting to Topwell WeldNET, you can pre-control the parameters, monitoring the process at real time, and trace the quality, thanks to the equipment, production, and process management modules. Meanwhile, your productivity and quality are boosted with analytic and statistical tools. It unleashes the potential of your future welding production.

Robot interfaces are inserted via digital port (EtherNetlP, DeviceNet, CAN, CANOPEN, RJ485,etc.) with built-in communication protocols. No additional external communication modules are needed.

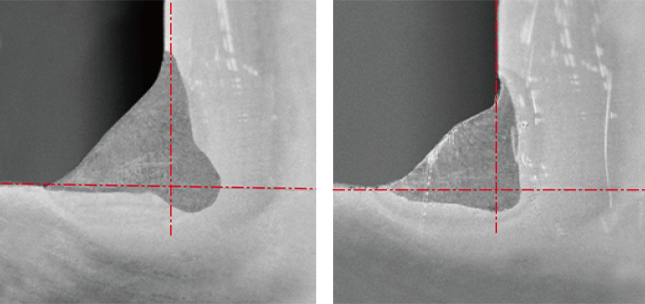

Better Aluminum Welding Process

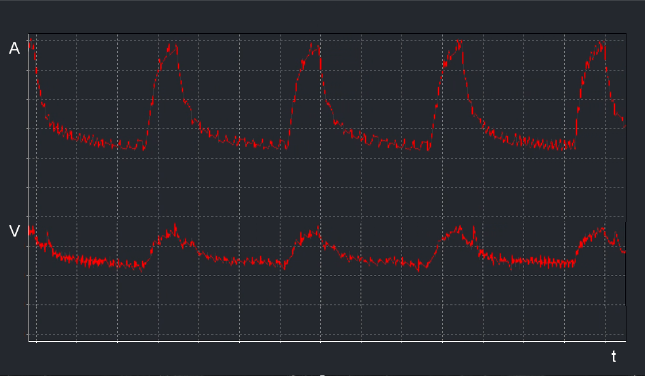

Benefited by the full-digital controller of the Pulse Arc process, it delivers:

Besides, by the refined and extensive expert database continually, always the Pulse Arc waveforms also updated accordingly.

As a result, it achieved deeper, focused penetration with minimal thermal stress, making it the ideal solutions for less-distortion, spatters-free welding applications especially the Aluminum welding jobs.

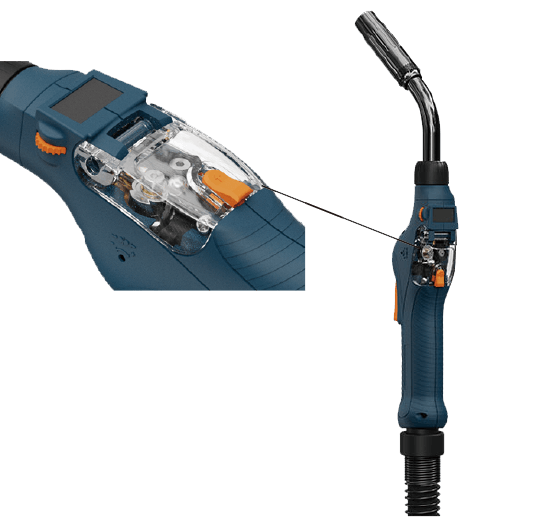

Using the most durable motor and drive design, and installing the wire drawing motor close to the welding position, the wire feeding is smoother and less likely to get blocked, especially in aluminum welding conditions, which improves wire feeding performance and arc stability.

Equipped with LCD screen display and function keys, it can communicate with the power machine to adjust welding procedures and parameters. Communication between the digital welding torch and machine enables enhanced the synergy welding, as the wire speed increases/decreases, the MIG parameters increase/decrease to match the appropriate power required.

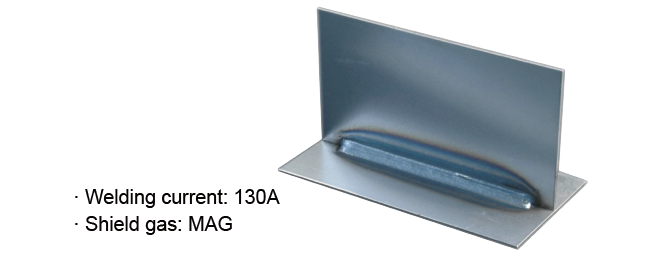

Refined Steel Welding Process

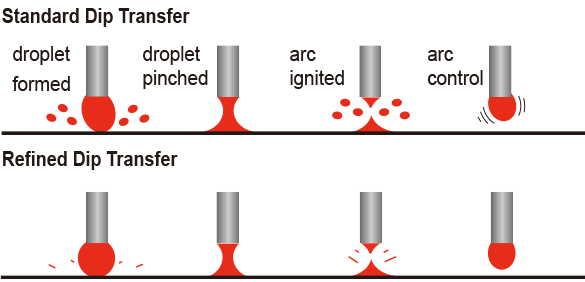

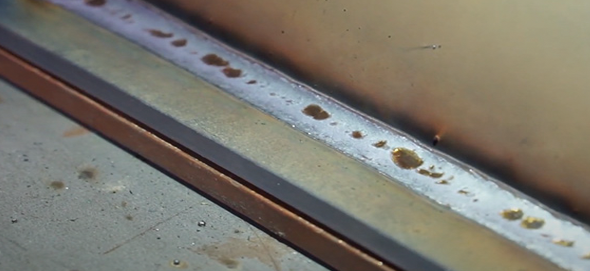

Refined Dip Transfer

• Highly efficient dip transfer arc with refined waveform;

• Suppress the spatter during short-circuit transition;

• Create high-quality seams with increased deposition rate;

• Spatter can be reduced by 20% when welding with CO2;

Improved Arc Length Controls

The extension self-adjusting function maintains the stability of the same short arc length, enabling constant and regular short circuits, despite the change in the welding torch position, changing sheet thicknesses, or material misalignment.

Benefiting from the wire feed control, the penetration stays stable and constant even in spite of the extension fluctuations.

Advanced Technologies for Higher Efficiency

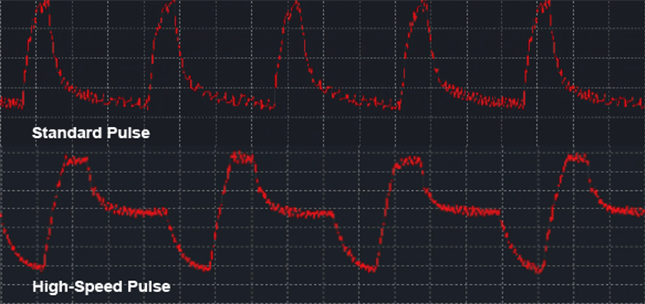

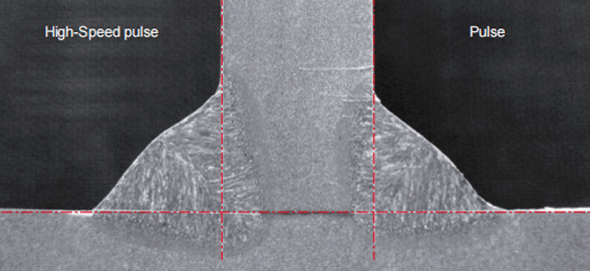

Compared to a standard pulse process, the HSP extends its transition to a virtually flowing material transition to the work pieces, which boosts deposition rates by 35% while ensuring smooth, spatter-free seams. It helps users to save time, money, and resource as no reworks are required.

Get better welding seam Less heat input, less spatters, less rework.

Get higher welding strength Deeper penetration, no undercut defects, higher strength.

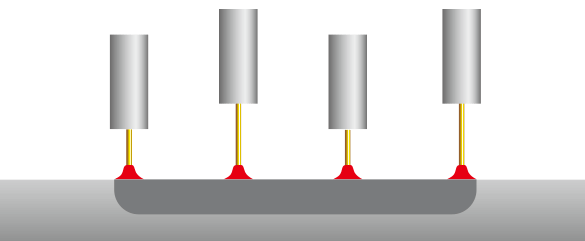

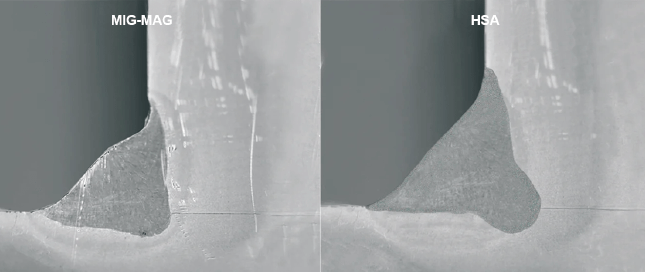

With a highly concentrated and extremely stable arc in high density, the HSA process delivers spatter-free weld seams, deeper penetration and narrower heating affected zones. It is also possible to weld at small opening angles with the high directional property. Its welding speed is more than 30% faster than conventional MIG or MAG welding.

Smaller opening angle

Deeper penetration

More material saving

Higher welding efficiency

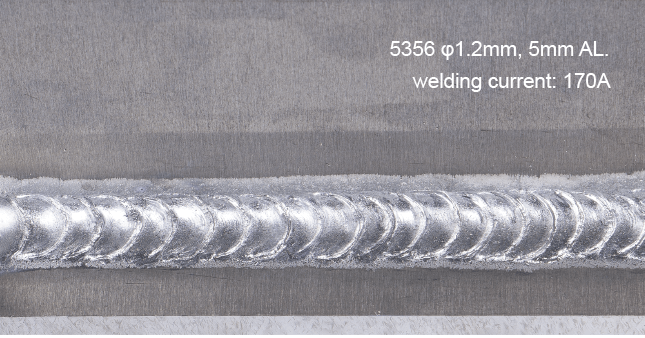

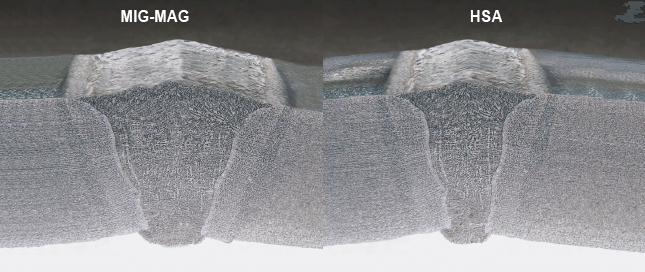

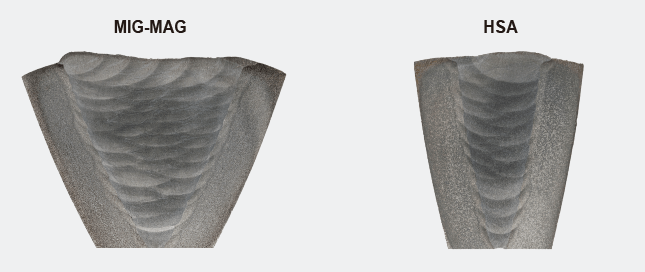

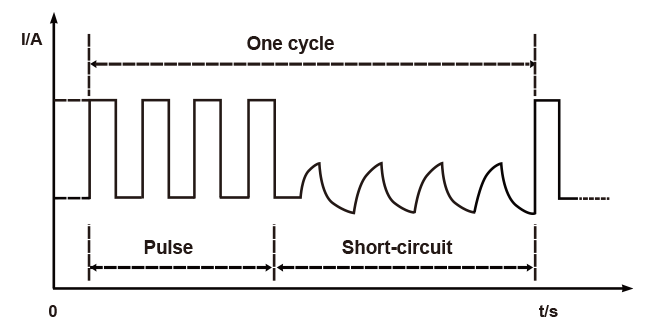

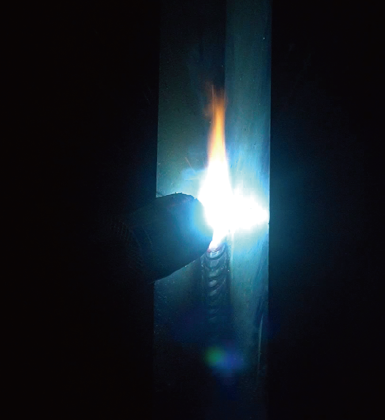

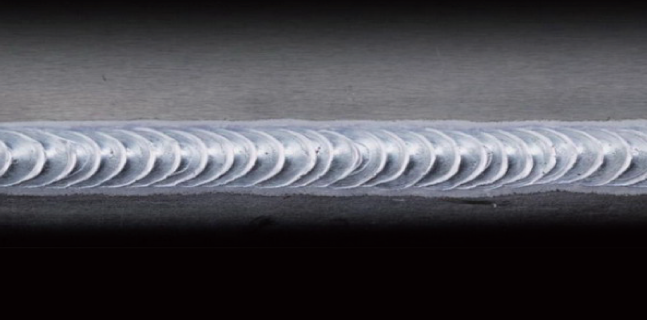

HPC--Hybrid Pulse Control is an advanced hybrid process that integrates Pulse and Short-Circuit transfer methods. By alternating between these two modes, the molten pool is heated and cooled periodically, creating a distinct "fish-scale" ripple pattern. The frequency and duty cycle can be precisely fine-tuned to shape the bead appearance as required. This exceptional puddle control makes HPC ideal for all-position welding, particularly for challenging vertical-up applications.

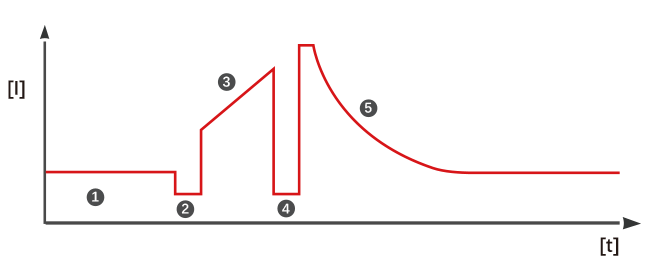

The specialty of HPC-Vertical Up lies in two processes: one is to heat up the material with high energy, and another is to steeply lower the heat to contribute to the well-formation of seams within a short time.

It ensures a reliable penetration, precisely sized weld fillings, and a near-optimal throat thickness and is faster and easier than the conventional "X-Mas tree".

With MDP, weld seam can be improved from coarse to fine. The key is that there is no droplet formation in the low pulse phase when the high and low pulses switches. Thanks to the precise energy input, MDP can deliver perfect TIG-like welding appearance but is twice faster than TIG. MDP is particularly suitable for thin to medium-walled (1-8mm) Aluminum, Steel, and Cr-Ni applications, like frames, tables, beds, and furniture structures.

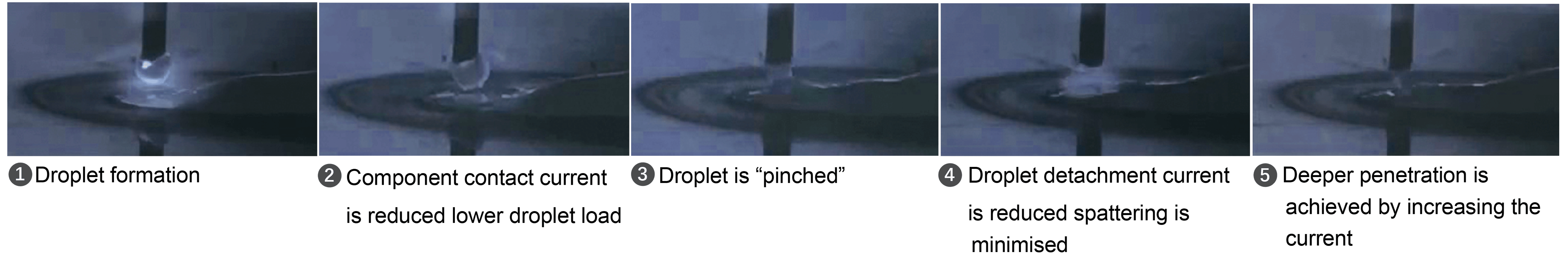

The ULS process is a modified short-arc transfer arc with perfect waveform setting that greatly reduces spatter generation. In the pinch phrase, there is a special current interruption, the energy is extracted under the program setting, avoiding the explosion caused by the large current, and the surface tension of the molten pool warms the generated droplets. Even in CO2 and MAG welding, it can minimize the spatters, which means less rework, fewer rejects, less cleaning required and savings on wearing parts.

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号